To Know About Us

Raagam Exports is a Government Recognized Two Star Trading House commenced in the year 1987 in Tirupur, the apparel city of India.We are a team of committed and dedicated professionals with a desire to serve the everchanging today's fashion world, and to be a momentous force in "Fashion for the trendy people".

We are constantly working with our customers to develop the most up-to-date fashion. With an annual turover of 7Million USD the company exports to the UK, Canada, France & Spin.

To be a compettive and renowned supplier of knitted garments from India and to promote green energy.

As manufacturers and exporters of cotton knitted garments our strength lies in intraducing innovative products which are not only unique and appealing but also very customer-focused.

What we have

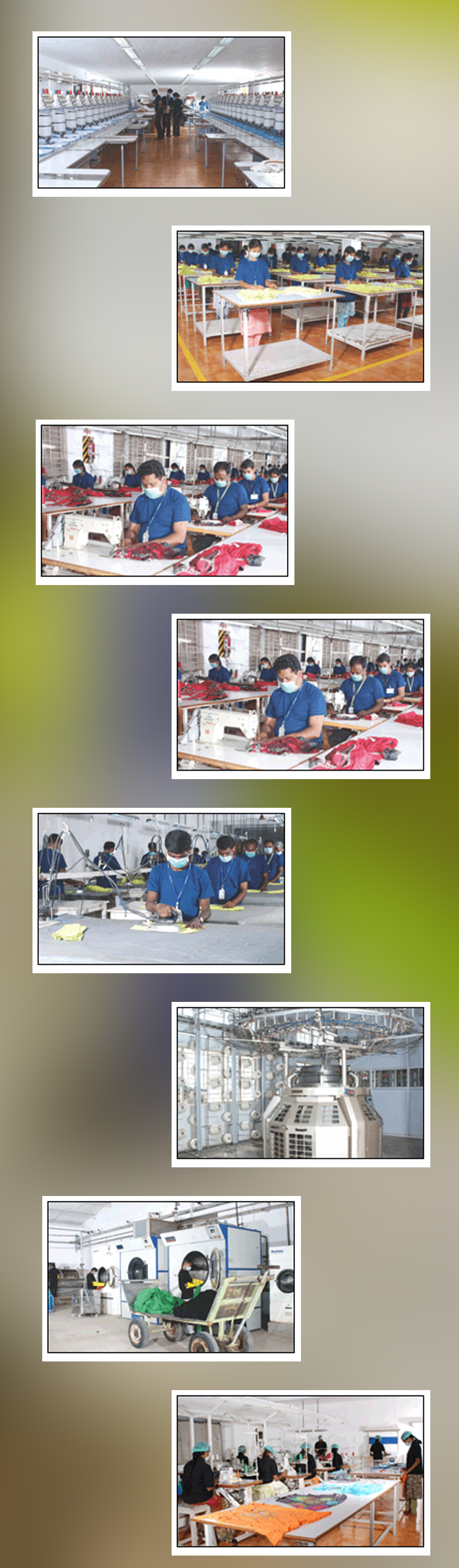

Lay-Cutting :

Garmenting division is equipped with Lay cutting (Spreader) France helps to meet mass production targets and has a capacity of 10000 pieces/day. It is well supported by straight knife and Band knife cutting machines from "Eastman", "Wastema" & "CUT & FIT".

Quality Checking:

Stringent checks are exercised to ensure quality and safety standards are adhered to AQL standards are maintained at the grade of 1.5 for smaller quantity to 2.5 & 4.0 for bigger quantities Periodic checks are executed with inspection formats at all levels and on the basis of Inspection reports, the defects are analysed and subsequently, corrective actions are taken.

Sewing :

An experienced and agile workmanship skillfully handles the complexities involved in stitching. 350 high-end sewing machines and line system helps to meet mass production. Regulating our quality aspect enables it to brace on the sewn garment.

Finishing :

Efficient and impressive work force of trained technicians, technical professionals and modern machinery work in tandem to bring about the finest finishing touch possible and what the customer envisages.

7

9

12

Knitting, the initial and key process for our industry helps in producing knitted fabrics. The State of art machineries from UNITEX, SINGAPORE helps knitting various kinds of knitted structures to meet out the market trend.

To emphasize eco-friendliness, we have modern Effluent Treatment Plant (ETP) and Reverse Osmosis technology to ensure no harm to the environment. We recycle water and re-use Glauber's salt with the perfect combination of dyestuffs for appropriate colours. Equipped with latest machineries for all consequent process, our productions turns out to 7 tonnes per day meeting our own requirement. All the efforts are towards providing the desired colours for our customers.

Washing is done to the garments to derive the different kinds of vintage effects and soft feeling that is required by our international buyers. Different washing techniques that can be done are Acid wash, Bio wash Silicon wash and Stone wash.

Fabrics are pre-shrunk so that the garments that we craft stay in shape, always. For this the processing division is equipped with the latest compacting machine imported from TUBETEX, USA that ensures all fabrics are compacted to perfection before garmenting.

We have in-house lab facility and we test the fabric for Shrinkage, GSM, Color Fastness to Washing & Rubbing. The color matching cabinet is used to match the colors of the required fabric with the shades provided by the buyer. Laboratory is outfitted with the state-of-the-art equipment and staffed with highly trained, experienced technicians who are able to conduct a wide range of procedures.

The purpose of sampling is not only to get bulk orders and also to give some additional benefits to the exporters. By doing sampling the exporter can estimate the yarn consumption for developing the fabric., a clear idea on costing more ever the manufacturing difficulties. The samples decide the ability of an exporter. The buyer will access the exporter and this organisation only by the samples. If the samples are of good quality and with reasonable price naturally the buyers will be forced to place the order.

Embroidery a value addition and an art that increases the garments exotic value. Equipped with 6no's of sophisticated Japanese "BARUDAN" machineries, enables mass scale execution of intricate embroidery upto 9 Colours.

Printing, one amongst our strengths is equipped with three latest and advanced chest printing machines imported from M&R, USA. We are capable of producing innovative, trendy and customised designs in dicharge, pigment, Non- PVC and plastisol Prints, upto 12 Colours. Five Gas Curing machines from ANSAL, TURKEY help us in enhancing the print fastness onto the garments.

Some Samples of our Products